At the same time, this speeds up installation when renovating building envelopes. Visitors to ‘BAU’ can view two versions of the BIPV facade elements at the Fraunhofer Allianz Bau stand at the Munich trade fair from 13 to 17 January 2025. The facade element was developed as part of the Fraunhofer lead project ‘BAU-DNS’.

The researchers at Fraunhofer ISE and Fraunhofer UMSICHT developed two versions of the 1 x 1.2 metre facade elements: One with an insulating material made of hemp fibres and one with insulation consisting of a mushroom material. The insulation is inserted into the BIPV facade element in such a way that the components can be separated again by type at any time.

Made from renewable raw materials

‘Both insulation materials are made from naturally renewable raw materials, making them CO2-neutral and circular,’ said Holger Wack, Group Manager for Building Material Development at Fraunhofer UMSICHT. ‘Both materials are suitable for use in facades in terms of their fire behaviour. The mushroom material can also be produced from agricultural industry waste and is therefore very resource-efficient.’

See also: The right level of performance from these colours for PV facades

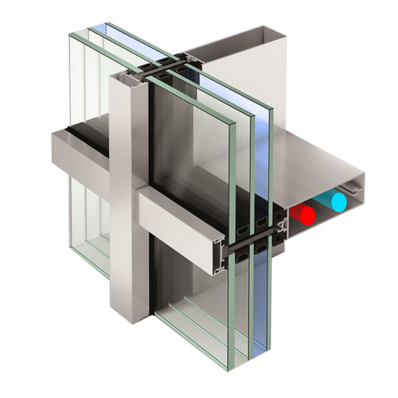

The facade system developed by the research team allows individual BIPV facade elements to be dismantled independently of neighbouring elements. BIPV facades can therefore be implemented quickly and easily in building class 1 to 3 applications. By eliminating a substructure, large amounts of material are saved compared to classic constructions for building-integrated photovoltaics (BIPV) with a ventilated curtain facade.

First prototypes installed in southern Germany

The scientists installed the first prototypes produced at Fraunhofer ISE on a Fraunhofer IBP building in Holzkirchen near Munich in late October 2024. The PV facade elements are now under intensive monitoring there in order to test their electrical yield, durability, temperature and humidity behaviour as well as thermal insulation properties in use.

‘We have already been able to confirm the ease of installation without special installation aids such as holding systems and the associated high installation speed of less than 1.5 hours per module in this first demonstrator,’ said Jan-Bleicke Eggers, Team Leader Solar Building Envelope Technology at Fraunhofer ISE.

Also interesting: New technology transforms windows into a source of solar power

Future construction projects will also be supported by a digital process description for the correct design of the building-integrated photovoltaic system and for installation. Visitors to BAU can also familiarise themselves with these at the Fraunhofer stand.