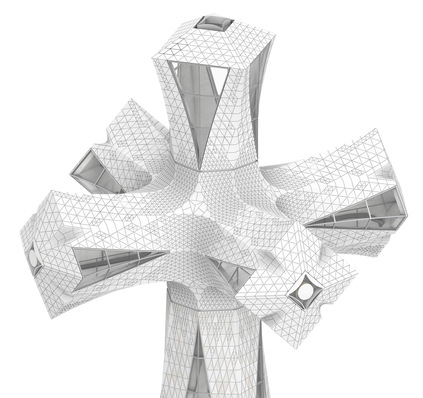

In Basel, Roche is concentrating its pharmaceutical research in the pRED Innovation Centre, which opened in September 2024. The two laboratory buildings, which are up to 114 metres high, have a Closed Cavity facade (CCF) from Gartner. For pRED, Basel architects Herzog & de Meuron designed four independent individual buildings that are staggered in ascending height: an 18 m high congress centre and a 26 m high office building with ribbon windows in timber construction and white parapet bands as well as two high-rise laboratory buildings. Two glass bridges connect the laboratory towers on the 6th and 13th floors.

What does the facade do?

Roche Ltd / Beat Ernst

The CCF building envelope contributes to an inspiring working environment for around 1800 researchers from various disciplines. With good daylight utilisation, high sound insulation and pleasant air conditioning with very high energy efficiency, they meet the very high requirements of pRED's green building concept, including Cradle to Cradle.

See also: Mastering mullion-transom facades is an art - DelftX shows how it's done

Roche also aims to reduce subsequent operating and life cycle costs with the CCF, as they allow for easy maintenance cleaning and the sun shading is housed in the protected space between the facades.

The CCF facades achieve g-values of g(total) = 0.1 (blinds closed at the bottom) to g(total) = 0.33 (blinds at the top).

The sound requirements were all met or ‘exceeded’. For longitudinal sound insulation, 68 dB was achieved vertically and 58 dB horizontally. The airborne sound inside and outside was not measured, as the requirements of > 38 dB were exceeded by the CCF.

What exactly did Gartner produce?

In total, Gartner manufactured around 32,000 square metres of CCF facades for pRED, as well as around 8,000 square metres of other facades for the congress centre and the office building. These include a 2.7 m wide and 1.9 m high baffle plate construction made of aluminium with curved corners with a radius of 3.4 m.

This 11.5 m long and 4.85 m wide mullion and transom construction, including glazing, was manufactured at the main plant in Gundelfingen, then delivered to Basel by special transport and installed using a 140 m high crane.

René Dürr, Zurich

These facade glasses were installed

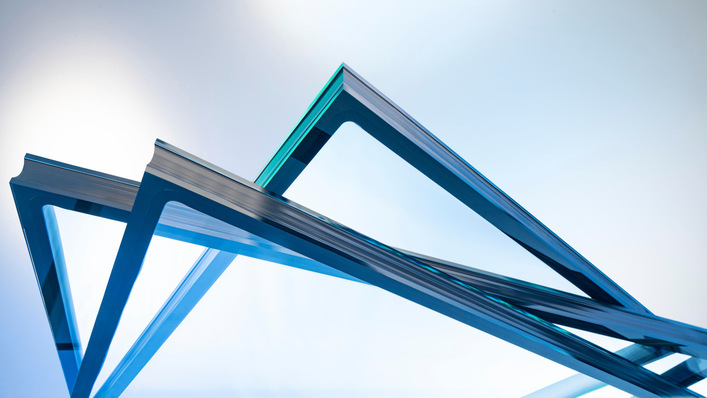

The 5250 CCF elements are up to 5.5 m high and 1.36 m or 1.45 m wide. These closed elements are glazed on the outside with a baffle pane made of LSG (base = white glass) and on the inside with Triple insulating glass (base = white glass), each with a solar control and thermal insulation coating (item two ipasol ultraselect 62/29; item five iplus 1.1 from Interpane). Between the outer and inner glazing, there are 80 mm flat louvres in the cavity as sun shading.

Also interesting: Flexible warm edge spacer systems in Copenhagen and Luxembourg

Stainless steel sheets up to 5.5 metres high with a concave radius of 565 mm with mirror glass are integrated into the corner elements of the CCF. Gartner developed a motorised counterweight traverse with a controllable blower especially for the installation of these elements, which weigh around 1600 kg. This allowed the fitters to counteract the wind - similar to a hovercraft - to prevent uncontrolled rotation of the elements.