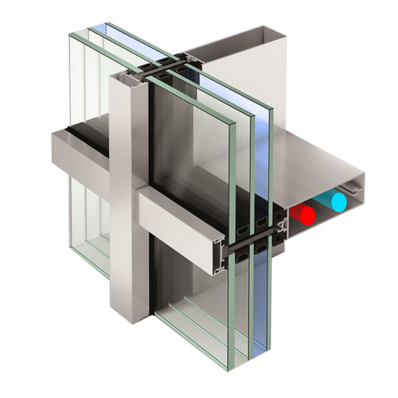

Structural glazing facades - i.e. bonded all-glass facades without a visible substructure and with minimal joint widths - are among the most demanding building services. The fine interplay of insulating glass units, mechanical substructure, bonding and sealing must be optimally coordinated to meet the high safety requirements.

The adhesives and sealants used in SG facades must permanently withstand all climatic stresses to ensure building safety. A decisive feature for this is the compatibility of the adhesives and sealants used, not only with each other but also with all other materials in the facade.

H.B. Fuller | Kömmerling

Caution with diffusion processes

Special care must be taken with so-called diffusion processes, and this actually applies to materials that are not in direct contact with each other: If the compatibility in the entire facade system is not sufficient, diffusion processes such as plasticiser migration can occur and cause damage to the construction.

The material between the incompatible substances acts as a contact bridge, which can change the adhesives and sealants involved. Visual impairments tend to be a harmless consequence, but very elaborate and costly repairs may become necessary. Engineers, planners and architects should therefore attach increased importance to the compatibility of all materials used.

What materials need to be tested for compatibility?

The materials that must be tested for compatibility include the glass used and the edge seal (spacers and sealants) of the insulating glass elements as well as the silicone adhesive used to bond the SG elements to or onto the substructure. The other materials used, such as backfill cords, spacer tapes and weather silicones, and of course the surfaces of the substructure, must also be taken into account.

H.B. Fuller | Kömmerling

The dimensions of the structural glazing joint and the secondary sealing in the insulating glass units must also be calculated or designed and executed in accordance with the legal requirements for structural glazing facades. Perfectly coordinated adhesives and sealants from a single source, such as the manufacturer H.B. Fuller | Kömmerling, reduce the risk of incompatibilities in the entire system. If the supplier also has the necessary expertise to train the applicators and carries out adhesion and compatibility tests himself in a laboratory, important prerequisites are already fulfilled.

Why are only silicones approved according to ETAG 002?

The requirements for structural glazing constructions are regulated by the "Guideline for European technical approval for bonded glass constructions" (ETAG 002). The manufacturer of the adhesive must have its own European Technical Approval (ETA) for its material.

See also: Liquid lamination without edge seal

Only silicones are approved according to ETAG 002, among other things because of their high UV resistance. The silicones certified according to the standard have undergone an elaborate test programme that assumes a service life of at least 25 years for the structural glazing bond.