As the size of the windows and doors increases, greater requirements are also placed on the materials used - partly due to the high weight. What is technically feasible also depends on the seals used for such systems. On the one hand, these have to protect the interior of the building from weather effects such as moisture, wind and cold. On the other hand, they must enable the systems to open and close silently. This requires special properties for the seals, such as a friction-reducing surface and protection against abrasion and material damage.

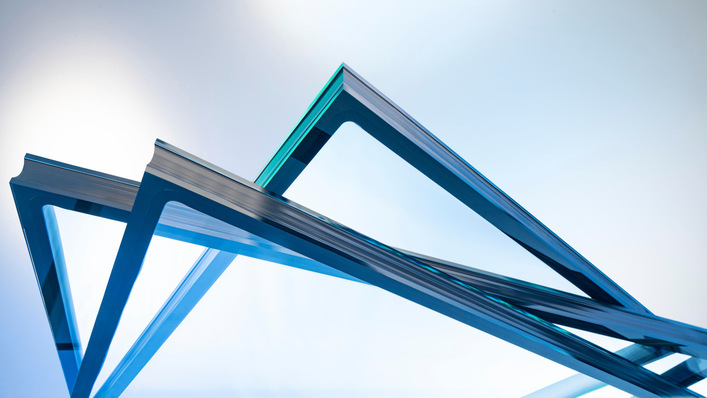

Speaking of large windows:

sedak recently installed the largest tripple IGs in the world

“Due to the permanent stress, the risk of wear and discoloration of the seals increases. Therefore the profiles have to be protected accordingly,” says Franz Haas, project manager at Trelleborg Seals & Profiles. The company uses two techniques to achieve better sliding properties: Sliding varnishes can be applied partially to the surface of the functional areas of the sealing profiles. Or, as an alternative to the sliding varnish and for very highly demanding applications, Trelleborg applies a high-performance film specially adapted for these applications to the seals. This is also responsible for the good mechanical properties of the sealing surface.

The premium coating used is characterized by high abrasion resistance (comparable to steel), very good impact resistance, a low coefficient of friction and extensive resistance to chemical substances. The coating is available in widths between 6 and 16 mm. Other dimensions are available on request.