In comparison with a conventional warehouse with A- and L-racks, these compact storage systems provide many more of rack positions. Smaller compartments offer the option to store a greater variety of products. Larger holds have the space required for accepting larger quantities of one type.

Be it manual, motorised or wirelessly controlled – compact storage systems can be adapted to individual needs. The KPL-MZ, manual storage system, was designed for companies that require smaller quantities and a greater variety of products. It is also suitable for holding glass panes for special cutting. To take out a glass pane, a crank creates an opening that allows safe, scratch-free removal. Hegla also offers a remote-controlled motorised variant: the KPL-F. Access to a specific hold is triggered via wireless command and can be closed directly after removal.

Hegla

Automated storage management and inventory

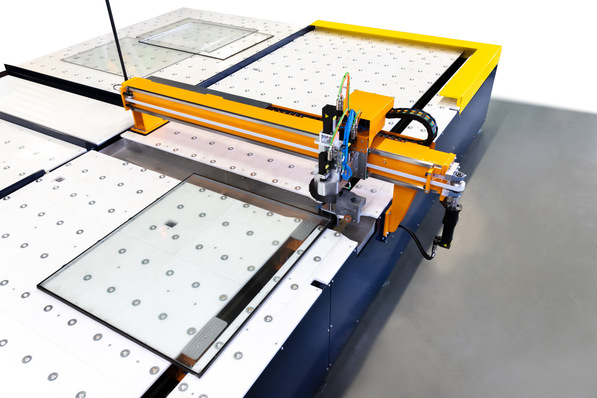

The KPL-A automated storage system can be integrated into the production software, all processes are system-controlled, motorised and precisely harmonised to the glass flow. The storage positions are located to provide quick access for loading. On the one hand, they increase the variety of products in the glass storage system while also enabling additional sizes to be stored.

See also this article: New logistics centre for the Fenzi Group in Italy

Integrating the glass storage system into a storage management system, allows accurate inventory at all times, tracking which glass has already been reserved for production and whether or not more panes have to be or have already been ordered.

These glass storage systems are modular which means that they can be adjusted to suit a variety of production requirements and glass dimensions.

Hegla