"High-quality cullet is key in the production of CO2-reduced glass," said Dr. Stephan Kranz, Managing Director of Saint-Gobain Glass Germany at the signing ceremony, "The partnership between Saint-Gobain and Ragn-Sells is another important building block on our carbon roadmap to CO2 neutrality!"

The glass manufacturer's goal is to achieve a cullet content of 40 per cent in float production by 2040. Campaigns like that of CO2-reduced glass called Oraé, which is actually up to 70 per cent cullet-based, are a clear step in this direction. This underlines the importance of such a partnership as Saint-Gobain Glass, together with players such as Ragn-Sells, aims to lead the market towards the decarbonisation of the glass industry.

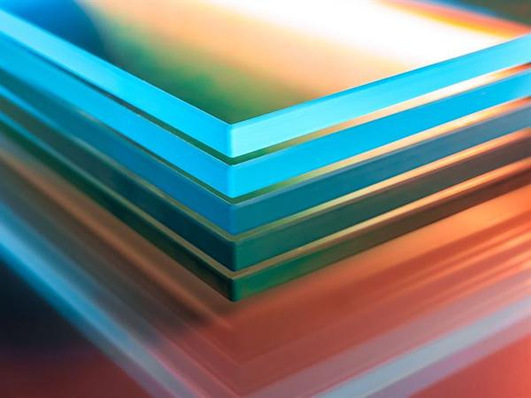

Giving the production of low-CO2 glass greater momentum

Saint-Gobain Glass

Through the cooperation agreement, active cullet recycling and thus the production of CO2-reduced glass are gaining momentum. The first projects with recycled facade glass have already been acquired and will be supplied by Saint-Gobain Glass.

In addition, another circle is closing. The Scandinavian recycling company Ragn-Sells will initially process deconstructed glass facades, mainly windows, from demolition and renovation projects in its own facilities, primarily in Sweden and Norway. Afterwards, the cullet will flow into Saint-Gobain's production. Another goal is the optimised utilisation of the transporters, i.e. the loading of transport vehicles in both directions.

See also: Glass recycling: urban mining in Stockholm

Saint-Gobain's largest glass recycling project has already been successfully implemented: In the former SAS headquarters "Gate: 01 Frösundavik", the individual glazings were dismantled, processed and 50 tons of glass successfully recycled.

What does the cooperation partner Ragn-Sells do?

Ragn-Sells ensures the high quality of the cullet needed for glass production by professionally dismantling the glass, separating it according to type and then processing it. The first processing plant at Ragn-Sells is in operation near Stockholm.

Incidentally, cooperations of this kind are also being expanded in Germany, for example, in order to be able to offer recycling in redevelopment cases. Through the partner "Polygon Recycling" it is now possible to offer a cost-neutral take-back of PVC and aluminium windows for building owners.

Saint-Gobain Glass

CO2-reduced glass from Germany

The Ragn-Sells Group collects and recycles 1.5 million tonnes of waste annually, which is used for both material and energy recovery. Professionally processed cullet will in future be processed at Saint-Gobain Glass Flachglas Torgau.

Also interesting: What financial benefit does window renovation really bring?

The CO2-reduced Oraé glass produced there will be available mainly for the facade market and will make a significant contribution to the construction of CO2-reduced building envelopes and thus contribute considerably to the conservation of resources. An EPD is currently being prepared, which will provide a verified data set for the planning of sustainable buildings.