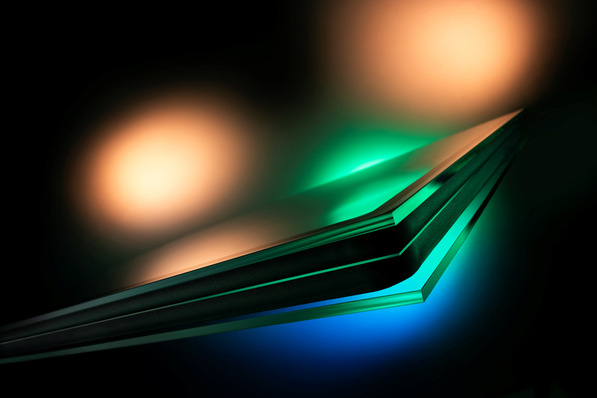

The modernity of the Croatian museum and the experience offered to visitors are reflected in the environment and materials used for the displays, with laminated glass playing a crucial role. Laminated glass is extensively utilized in various areas of the museum, including a timeline dedicated to the development of local pharmacy, where it enhances both the educational journey and the aesthetics of the museum spaces.

Strato EVA:

The client’s aesthetic and performance requirements were met effectively with the use of two EVA films from the Strato series. This range of Italian-made interlayers, available in different colours and finishes, was employed to create specific curved laminated glasses.

Satinal

Strato Latte:

This EVA film is ideal for interior lighting due to its ability to allow light to filter through the glass without reflections. It diffuses light uniformly, and the satin texture from the Strato Frost line creates harmonious frost effects even on curved surfaces.

Strato Extra Clear:

A high-transparency interlayer suitable for internal and external use, ensuring optimal light transmission while filtering over 99% of UV rays, providing maximum protection.

The resulting curved laminated glass combines high aesthetic elegance with superior resistance, lighting, transparency, and UV protection.

Also interesting: Massive window for luxury hotel in Rovinj in Croatia

Satinal, leveraging the versatility and numerous combination possibilities of the interlayers in the Strato line, has applied its technical expertise in the glass industry to support cultural dissemination to the general public.

About Satinal

Satinal is the manufacturer of the Strato EVA interlayers which are entirely made in Italy. Satinal offers a wide variety of products to meet the needs of their customers. The quality controls, which are carried out in Satinal’s R&D Lab, aim to guarantee perfect adhesion of the material to the glass surface. The deep experience acquired by Satinal in the treatment of EVA-based materials is essential to master its potential applications and fully exploit their characteristics.

For more articles on interlayers for laminated glass, click here