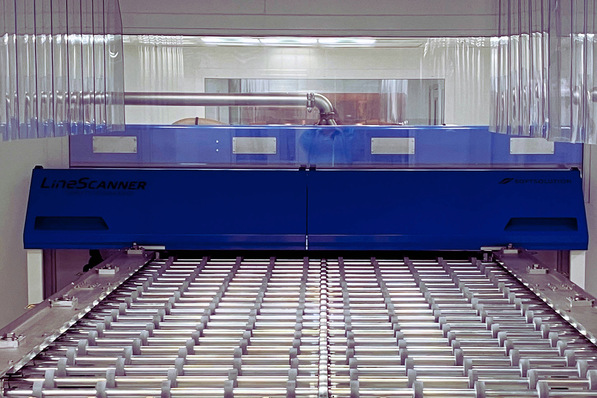

The fully automatic Lisec insulating glass line VSA, used for applying flexible spacer bands to glass sheets - has only recently gone into operation. Glass Madrid Berlanas operates the first of them anywhere in Spain.

The company of 70 staff is headed by the joint managing directors Antonio Fernández, Antonio Gómez and Natanael Fernández, who manufacture a wide range of products in the 11,000 m2 production halls, for use in building and architectural projects: Windows, exterior railings, facades, exterior and structural glazing, but also sheets of glass for skylights or outdoor furniture are just some of the products.

All in all, there are four glass cutting lines, two smart glass storage systems, two insulating glass lines for double and triple insulated glass, four glass bending furnaces and many more machines for drilling, milling and edge processing. And the first fully automatic system for applying flexible spacer bands to glass sheets, the VSA from Lisec, is only the latest addition.

Lisec

In this interview, Antonio Fernández, one of the three Managing Directors of Glass Madrid Berlanas, explains his reasons behind choosing the VSA from Lisec:

Mr Fernández, how did you first find out about this Lisec solution in the field of insulating glass production?

Fernández: The Lisec team provided us with sound information about this machine and the relevant salesperson, Enea Dullori, took great care to ensure that the solution we were looking for also met our requirements. The main problem was that the previous machine lacked a fully automated production process, which resulted in lower output, higher costs and, to some extent, poorer quality. The VSA has provided us with a solution that addresses precisely this issue. We have also learned about various marketing channels of Lisec, such as the product videos, in which the machines are well explained with the corresponding functionalities. This was very helpful in getting relevant information during the pandemic.

How do the benefits of the machine translate into production?

Fernández: Most importantly, of course, we can recognise the advantages that automated processes bring with them. We require fewer operators, save on energy costs - in a nutshell: We are more energy efficient and have perfect quality that lives up to our standards. This allows us to deliver more sustainable, faster and higher quality products to our customers. That is one of the reasons why we are so proud of this machine. The products we produce have a unique USP for our customer, as we use a high-quality machine for production that is unique in Spain!

Are there any other benefits of the VSA that were key for you?

Lisec

Fernández: Investing in a Lisec VSA Super Spacer applicator has helped us to significantly increase output in insulating glass production. The VSA saves us many work steps in production, especially when it comes to spacer frame production. The work steps of frame bending, filling with molecular sieve and applying the butyl as well as setting the frame by an operator are no longer necessary when using the Super Spacer applicator. These activities are now performed by the machine – at a continuous speed and quality. Furthermore, we are just one of the few suppliers in Spain that can offer insulating glass with Super Spacer flexible spacers, something that gives us a competitive edge.

Lisec promotes itself as being a reliable, competent and innovative partner – these characteristics are very well reflected in the machine and its functionality! Another aspect is that it is possible to operate the machine without any genuine previous experience - something that is a real added value when there is a shortage of skilled workers. It should be pointed out, however, that we are also training our employees on how to use this new machine in order to achieve the best results and performance from the machine as quickly as possible.

What are your objectives for the next five years and how can Lisec support you in achieving them?

Fernández: We want to double our turnover in the next five years. This sounds very ambitious, but automation in glass processing provides us with ample opportunities to achieve this goal. One of the next projects with Lisec might be the KSD. The newly used technology or rather the newly developed LiTEC tool certainly makes this machine a good starting point for a new joint project, especially if what is said about the speed of this processing machine is true.

Lisec