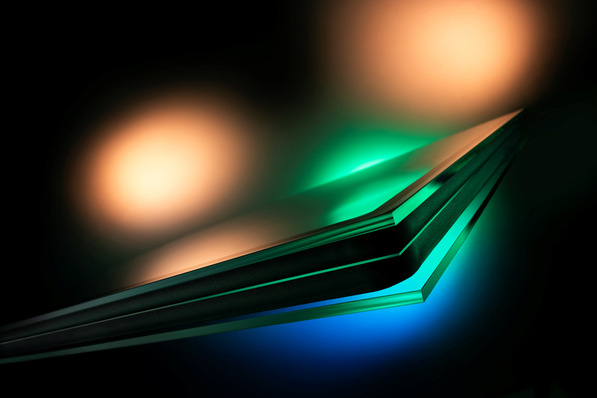

With Syn2tec, Lisec focuses on sustainability and efficiency. The recovery of valuable materials and the reuse of glass take centre stage. Syn2tec offers glass processors a forward-looking solution that combines resource conservation with easy handling and high flexibility.

Syn2tec technology enables the clean separation of insulating glass panes from post-industrial and post-consumer sources. Materials such as spacers, desiccants and sealants are removed without damaging the glass.

See also: Swisspacer to commission new recycling plant for thermoplastics

Lisec

The method developed by Lisec makes it possible to either reuse the recovered glass for new products such as insulating glass or to feed it into float glass production.

Scalable for different requirements

With Syn2tec, Lisec offers a scalable solution for entering the circular economy. The separation technology can be used in a variety of ways - from hand-held devices to automated high-performance systems. This flexibility allows glass processors an easy and cost-efficient entry into sustainable processes.

Manual cutting with IGD-A Manual

The IGD-A Manual hand-held device from Lisec impresses with its simple operation and high precision. It separates glass and spacers efficiently without leaving damage such as scratches or butyl residue on the glass edge. The safe operation and precise guidance make the Lisec manual device ideal for repair work on construction sites or for processing large quantities of insulating glass.

Automated cutting with a robot

In addition to the hand tool, Lisec has developed an automated cutting system that combines robot technology with innovative sensor technology. This system from Lisec enables precise cutting with cutting speeds of over 500 mm/s.

Also interesting: High-volume laminated glass production with a new machine

Thanks to its vertical design, it is particularly suitable for large and heavy glass panes, as its own weight prevents it from sticking together again.

Lisec