The first pull of glass completes the plant’s startup, which began with the groundbreaking in 2018 and led to the start of the plant’s technologically advanced new glass coater on July 6.

“The new float line is the largest in the Guardian family of float lines,” explains Guus Boekhoudt, Guardian Glass Executive Vice President. “We’ve implemented an innovative new furnace design with high efficiency combustion systems in order to provide products that meet the stringent quality requirements of our customers, while minimizing both the energy used for production and emissions from the process.”

Progressive design approach

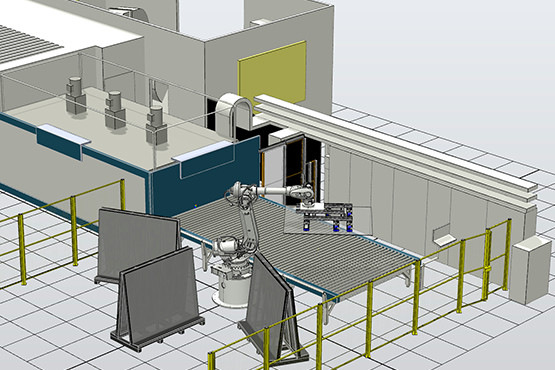

The plant, hosting two float glass lines, two coater lines and a lamination line, produces Guardian ExtraClear float glass, Guardian ClimaGuard low-emissivity (low-E) and Guardian SunGuard solar control coated glass products as well as laminated glass for residential and commercial applications.

Guardian Glass

By engaging suppliers to provide both proven and innovative solutions to meet production and quality requirements, Guardian Glass Europe took a progressive approach to the design for the new float line, underlining Guardian’s long-term commitment to its customers to be the preferred supplier of glass solutions.

One thousand tons of glass per day

“The Guardian Glass Częstochowa plant represents our biggest greenfield capital investment in Guardian’s history,” Boekhoudt adds. “This facility is the company’s most efficient and operationally effective plant and houses our largest furnace and largest coater. The new float line has a nominal capacity of 1,000 metric tons of glass per day, while the new coater represents the latest in technology for Guardian and, we believe, for the industry.”

See also this article:

Lasers now cut crooked edges

“We are grateful for the strong support we have received in Poland from local and national officials,” says Grzegorz Kuznik, Guardian Glass Czestochowa Plant Manager.