While the recycling rates for container glass in the EU reach up to 90%, flat glass recycling still has significant untapped potential. The primary challenge lies in the stringent quality requirements for flat glass recycling, which often render the process economically unviable. Hegla's IG2Pieces addresses this challenge by facilitating the separation of glass into its pure components, thereby making the recycling process more cost-effective.

Pure glass separation: a game changer

Traditionally, mixed glass containers, often filled with unsorted insulating glass units (IGUs), were the norm for disposal. However, the introduction of IG2Pieces offers a more economical solution by providing pure, sorted raw materials to IG manufacturers.

See also: Hegla invests 4.5 million euros into new logistics centre

Hegla

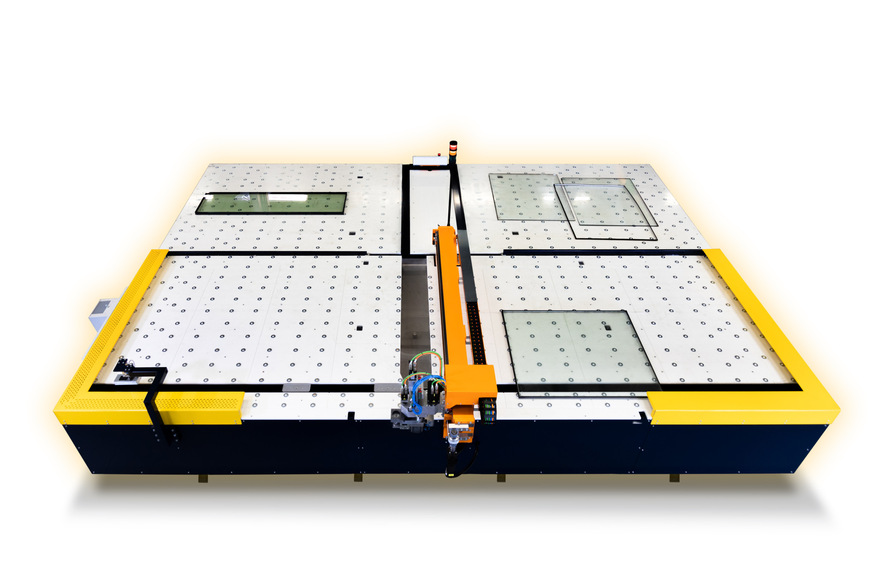

Heinrich Ostendarp, Managing Director of Hegla: "Our goal with the IG2Pieces separation solution was to ensure that IGUs are separated cleanly and safely, preserving the integrity of the components." The system is engineered for maximum efficiency and productivity, with short cycle times and the highest level of process security.

How the IG2Pieces system works

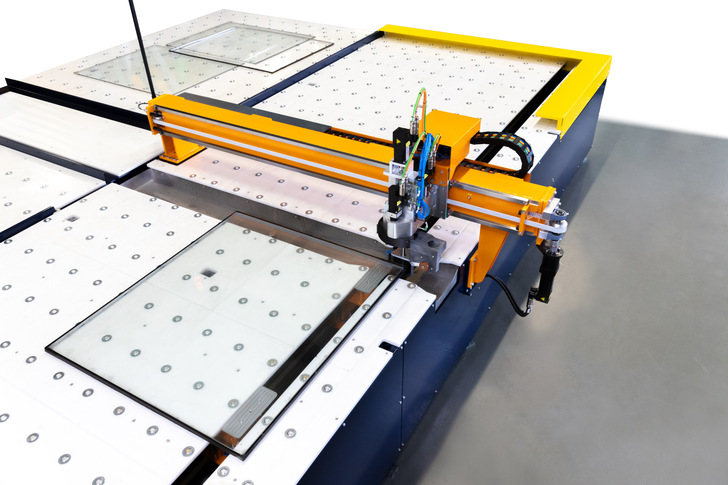

The automated separation of IGUs is the hallmark of IG2Pieces. The system features a novel separation process that dismantles insulating glass units automatically, leaving only minimal sealant residue on the glass. This ensures that the glass panes remain undamaged, and the spacer bar with its desiccant is also preserved.

In operation, the insulating glass is placed in a horizontal position where it is system-controlled for measurement and structural assessment. Simultaneously, the operator can prepare the next pane for separation.

Economic and environmental impact

The economic advantages of pure glass recycling are clear: Separated glass types fetch higher purchase prices from recyclers. Moreover, the practice positively impacts the optical quality of the end products, producing a more pure, untainted form of flat glass.

Also interesting: Unlocking the circular economy potential in the flat glass industry

Hegla

Recycling with IG2Pieces not only closes the material loop, allowing the glass to be repurposed through the float process but also delivers significant environmental benefits. For every kilogram of float glass produced from recycled material, CO2 emissions are reduced by approximately 0.3 kilos, contributing to a more favourable carbon certification.

The IG2Pieces system in summary

With IG2Pieces, Hegla has developed a system that is both economically and environmentally beneficial, helping insulating glass manufacturers reduce CO2 emissions and generate financial returns through efficient recycling processes. This innovative approach marks a significant advancement in the field of glass recycling, setting a new standard for sustainability in the industry.

For more details on Hegla's IG2Pieces and its impact on the glass recycling industry, be sure to come visit Hegla at glasstec 2024 in Düsseldorf.