“Curves are beautiful”, “The beauty of curves”. These are the two new concepts that Tvitec has started to apply to its fabrication of curved glass for the global architectural glass market. The Spanish company is running one of the largest plants in Europe for the processing of this type of product. More than 25,000 square meters equipped with state-of-the-art technology, never seen before in such a specialized sector. The new premises are located near Ponferrada, at the industrial estate of Cabañas Raras (León-Spain), right next to Tvitec’s main plant with more than 100,000 square meters of fabrication area.

The machinery that Tvitec has developed to process curved glass is able to produce two main solutions: annealed curved glass and heat treated curved glass. For annealed curved glass Tvitec is capable to fabricate large sizes with assorted geometries either in insulating glass, safety and acoustic laminates as well as printed glass. The result, based on a number of example projects already completed, is a really high standard of optic quality. And for heat treated curved glass, Tvitec offers cylindrical lites with an excellent finish.

Tvitec

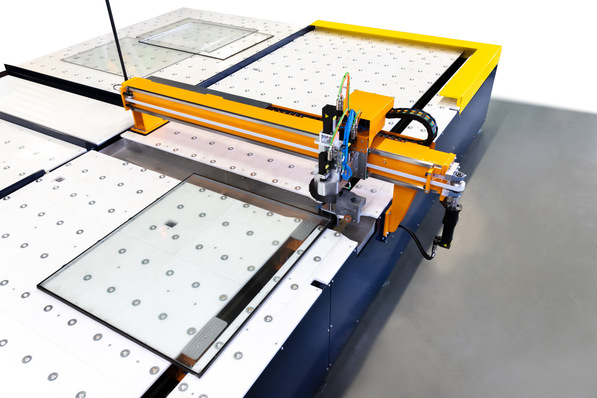

By using the Length Bending technology and depending on the glass size and overall thickness, a minimum radius of 500mm can be achieved. The Cross Bending technology allows Tvitec to fabricate sizes up to 6 meters with a radius starting at 2000mm. Curved glass products by Tvitec are processed on fully or highly automatized production lines. This makes it possible to offer solutions with shorter lead times and at more competitive prices.

Did you see this?

A glass roof for the motorway in Warsaw

Tvitec has a highly specialized technical team providing architects, consultants, contractors and facade builders with customized advice so that their projects can achieve from the very beginning a perfect balance between aesthetics, luminosity and sustainability on glass either for residential applications, office buildings, infrastructures or interior spaces.

Tvitec