Glaston develops advanced heating and cooling technologies for tempering flat glass for best glass quality, excellent energy efficiency and reliable automation.

Glaston FC Series EVO, the latest member of the FC Series, is a smart, energy-efficient and flexible solution. It features state-of-the-art convection technology with the highest energy efficiency. The line also includes state-of-the-art automation that ensures constant and flexible production.

See also: Healthy order situation despite uncertain markets

The Glaston Autopilot automatically sets all required parameters, reducing the need for manual operator input based on the placement of the glass sheets on the line.

And the online stress calculation solution uses measured process data to calculate the temperature and stress distribution in the

The White Haze Scanner is the first AI-based solution to provide a high-quality visual indication of white haze on processed glass. The system immediately notifies the operator of any irregularities, allowing the glass processor to react immediately if excessive haze is seen on the glass pane.

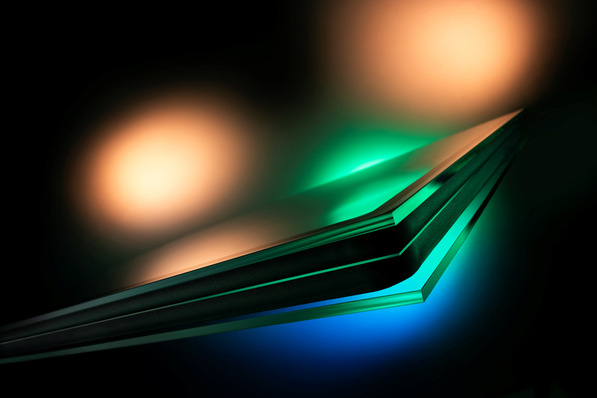

Laminating flat glass

The Glaston ProL flat glass laminating line offers very high flexibility for mixed production.

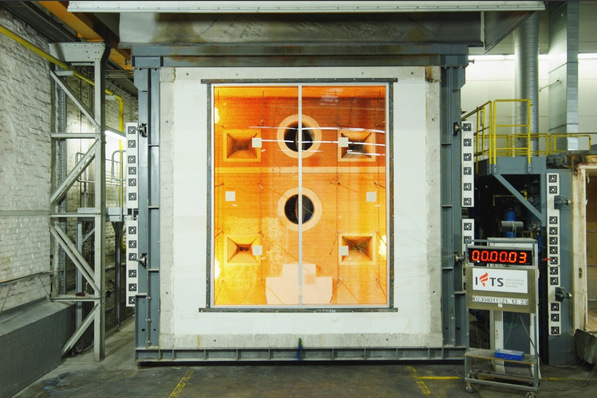

The convection heating chamber makes switching between glass types and different glass sandwiches easier than ever, according to the developers. From glass handling to the latest PVB cutting technology, the plant has been designed for flexible operation.

Echt Eppelt GmbH

Insulating glass production

The Active'Sealer automatic sealing machine is an ideal entry-level solution for the automated sealing process of double and triple insulating glass and targets the mid-range market segment. Using advanced gear pump dosing technology, the Active'Sealer offers high material dosing accuracy.

Also interesting: KAB Allglass from Hamburg: The only ESG manufacturer in Hamburg

The volume-controlled dosing function precisely determines the sealing depth and width and then applies the exact amount of sealing material required to the glass pane, ensuring a very good sealing quality.

The Active'Sealer sealer features air cushions and a new conveyor system consisting of individual belts with integrated and easily replaceable support bars for safe and clean glass transport.

Saving energy with upgrades

In the service area, Glaston offers new upgrade options for its glass tempering, IGU manufacturing and automotive and display glass processing lines. Upgrading an existing glass processing line with the latest technology (and controls) results in significant energy savings without having to invest in a new line.

Automotive and display glass

The Glaston Champ EVO is the latest development in the Champ line generation for pre-processing automotive and display glass. The grinding unit is a central element and has high-precision features.

The energy-saving and precisely adjustable linear drives significantly reduce wear and maintenance costs. A freely movable glass holding system shortens changeover times.

The Glaston Matrix EVO automatic bending furnace revolutionises the way windscreens and sunroofs are bent for the automotive industry. The system was specially developed for the high demands of today's automotive industry. It provides the best optical quality for even the most complex shapes and applications, including advanced driver assistance systems (ADAS), head-up displays and coated glass.

Glaston will be showcasing its products at Vitrum in Hall 7 / Stand H34 - K33