At the end of the 1990s, German chemist Michael Braungart and American architect William McDonough came up with the Cradle to Cradle concept. With regard to the construction industry, even during the construction phase the clients should think of its future demolition.

In simple terms, the aim is to avoid waste and to use raw materials that, at the end of the property life cycle, will ideally have the same value for new construction projects. For this, all materials used must be, as far as possible, able to be separated into individual materials, able to be dismantled, free of pollutants and recyclable.

Schüco International KG

BIM for sustainability and prefabrication

The building materials used in the project were documented in detail in a materials passport based on the BIM model. The digital planning also enabled a high level of prefabrication of the modular facade and a series module fabrication that saved time and costs. Despite its technical complexity, the entire facade of OWP 12 was installed in only two-and-a-half weeks.

A mini power station

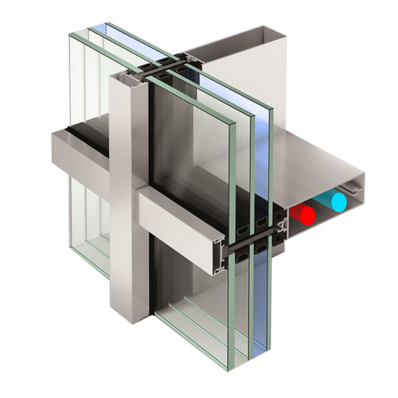

The e-coFace facade from FKN and Evonik combines high-end thermal insulation with sound reduction and consists of innovative, sustainable materials in several highly insulating layers. The aluminium profiles constructed by Schüco Engineering for this purpose have a basic depth of 90 mm and use the tried and tested internal design with thermal partitions, gaskets and insulation based on the AWS 75 aluminium window system.

The gasket and coupling system from the USC 65 unitised facade series was also used. The building will generate more energy than it uses. The energy generation comes from geothermal and air-heating pumps as well as from photovoltaic units that are both on the roof and integrated into the facade and glazing units.

BIPV in transparent and opaque surfaces

The Schüco BIPV which is on almost 700 square metres of the facade surface on the south and west sides of the building, has an output of around 70 megawatt hours per year. That is about 40 per cent of the PV output. Both transparent, triple-glazed insulating glass BIPV modules with black monocrystalline cells and black monocrystalline BIPV glass-glass modules were used as opaque, forward-mounted units in front of the main facade.

Also interesting: Innovative glazing solutions for museums and art galleries

Schüco International KG

"The requirement to reduce the natural reflection of the PV modules along the motorway due to traffic safety concerns was a challenge," explained Marco Schech, the leading project engineer for BIPV at Schüco. "We then finally found a special cover glass which significantly reduced the reflection, thanks to its unusual surface structure, and fulfilled the official requirements." An interesting side effect is that the solar energy output through this special glass is actually 3% higher.

BIPV as a design element

Schech sees BIPV gaining momentum due to new political requirements and a rethink among clients and companies. BIPV is also growing in popularity amongst developers because it enables interesting design effects and does not limit creativity.