Insulating glass lines more than 100 m long that are capable of processing oversize pane formats, i.e. washing, applying spacers, pressing, filling with gas and sealing, are making ever larger and more complex insulating glass units and thus applications such as structural glazing facades technically and economically feasible.

The sedak world record from 2020, in which insulating glass with a size of 3.04 × 19.21 m and an area of 117 m2 was manufactured and delivered, is impressive proof of this.

Edgetech

The further development of automatically processable insulating glass spacers as well as application machines has also contributed significantly to the XXL trend.

The tolerances for the parallelism of the spacer to the straight glass edge are now laid down in DIN 1279:1 006/2019. According to this, a deviation of 4 mm is permissible up to an edge length of 3.5 m; for longer edge lengths, the maximum deviation is 6 mm. Setting the spacer therefore requires precision work for optical as well as normative reasons.

For ISO formats that exceed the standard strip size (3210 × 6000 mm), assembled rigid spacer frames are difficult to handle due to their lack of rigidity and their tendency to deflect.

The spacer frame must be applied to the first glass pane in such a way that, on the one hand, it is straight and squarely connected to the glass and, on the other hand, it does not touch it until the final position is found. The range of application for rigid systems is therefore limited to certain glass sizes.

Flexible spacers are applied robotically from the roll on partially or fully automated lines at XXL specialists such as sedak and Interpane.

Since the desiccant is included in the spacer material ex works, time-consuming filling of the spacer frames is no longer necessary. In addition, there is no longer any risk of butyl residue, stains or fingerprints getting onto the glass pane.

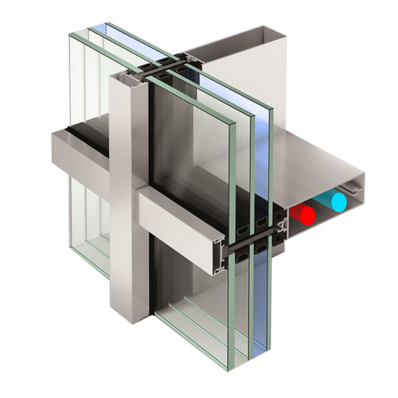

The shear strength of the IG unit

The shear strength, i.e. the integrity of the insulating glass unit, is ensured during production by the interaction of several factors: a sufficiently dimensioned sealant depth, the adhesive force of the spacer and PIB seal on the glass, and the grouting during the gas filling of the SZR.

Edgetech

The high adhesive force of Super Spacer spacers even with large-format glass panes was proven in a shear load test. For this purpose, a 6300 × 3300 mm ISO unit with two 6 mm thick float glasses was pressed without a secondary seal and therefore held together only by the acrylic adhesive applied to the side of the silicone foam of the Super Spacer TriSeal Premium Plus and the butyl cord. In a holding test of 30 minutes, during which one glass pane was lifted with the help of vacuum suction cups, the complete glass pane remained intact without slipping only 1 mm.

See also: Warm edge spacers are it in sustainable construction

Edgetech

The elasticity of the silicone material supports the integrity of the edge seal. The physical phenomenon of thermal linear expansion has a significance for the choice of spacer material for large, thermally broken insulating glass formats that should not be underestimated.

The coefficient of linear expansion for float glass made of soda-lime-silica glass is 9 × 10 e-6 1/K, that for aluminium 23 × 10 e-6 1/K, i.e. about 2.7 times. Thus, at a length of 20 m and a temperature increase of 50 Kelvin, glass expands by 9 mm, a 20 m long piece of aluminium by 23 mm. In the case of plastics, the thermal expansion is significantly higher again, depending on the material composition.

Since the expansion force acts on the entire length of rigid spacers, this quickly adds up to one centimetre or more per edge length for large formats. This may result in the spacer profile loosening from its position over time due to the stresses and protruding into the visible area of the insulating glass unit in the curve. The foam-based Super Spacer spacer accommodates these movements countless times thanks to its 100 % resilience.

If thermally separated composite profiles or structural glazing constructions are heated on one side on the outside due to solar radiation, the thermal linear expansion leads to permanent differential movements and thus a shear stress between the two shells. Metal spacers further amplify this "bimetallic" effect derived from electronics.

Also interesting: Is there still a place for aluminium spacers insulating glass?

The stiffer metal spacers cannot compensate for the resulting loads. Therefore, almost the entire shear load here is on a very thin PIB layer (butyl primary sealant and on the spacer's adhesion to the outer sealant; this can cause it to press into the visible area.

A flexible spacer is able to absorb this mechanical stress, as the forces are distributed among many local forces due to the flexibility of the spacer. The local adhesive forces across the spacer back, the primary seal and the additional acrylic adhesive applied to the sides of the spacer hold it in place and prevent the edge seal from being damaged, with all the known consequences such as gas loss, condensation, clouding and ultimately a shortened life span.