One of the focal points at the Glaston stand is the tempering of flat glass - with AI and automation: the latest tempering systems are the Glaston FC Series and RC Series as well as the Jumbo Series. All the furnaces are equipped with modern convection technology and offer maximum productivity and flexibility, according to the developers.

See also: A tower more than half a kilometre high

Laminating flat glass: In Düsseldorf, the Glaston ProL laminating line will be presented, which allows high flexibility for mixed production. The ProL convection heating chamber makes switching between glass types and different glass structures easier than ever. The entire plant - from glass handling to the latest PVB cutting technology - has been designed for flexible workflows.

Glass processing, insulating glass and more

Faster grinding: Another trade fair highlight is the Multi'arriser a 3-in-1 solution for hemming glass edges, glass surfaces and corners. With a maximum hemming speed of 60 m/min, the Multi'arriser is the fastest single-head machine in the world, according to its developers.

Better edges: As the developers say, the Hyperflex grinding system represents a revolution in glass edge grinding. The new grinding wheels have significantly improved performance parameters.

Also interesting: Glaston | Bystronic Glass: Taking glass handling to a new level

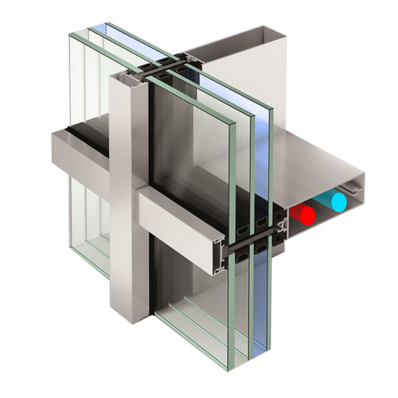

Insulating glass: TPS is not just a machine. It is a system solution for highly efficient insulating glass production. Because the production of insulating glass is significantly simplified, since the thermoplastic TPS spacer is applied directly to the glass. This means that spacer profiles and connecting pieces are no longer needed. The width of the TPS spacer can be changed as desired without interrupting production.

Active`Sealerist is a new sealer aimed at the mid-range market segment. And the Glaston Corner'Refiner enables automatic corner treatment of the ISO unit without an operator.

You can find Glaston at glasstec in Hall 15, Stand A40.

Glaston