Glaston, the pioneer of TPS (Thermo Plastic Spacer) insulating glass technology, is once again setting new standards. With a newly developed manufacturing technology, the company enables the production of Triple insulating glass units with an ultra-thin centre glass of as little as 0.5 mm - a technical innovation that overcomes challenges in the processing of thin glass and significantly improves the energy efficiency of insulating glass.

Patented production technology for thin glass

Conventional methods for manufacturing Triple insulating glass with extremely thin centre glass have so far been associated with considerable limitations. The biggest challenge: the fragile glass breaks easily under mechanical stress. Glaston has therefore developed a completely new approach, which was patented in autumn 2024.

See also: Interview: ‘I am confident that things will soon be moving forward again’

The key to this new technology lies in the precise control of the glass movement during the entire production process. The thin centre glass is fully embedded in the thermoplastic spacer and secondary sealant through optimised positioning. This both mechanically stabilises it and optimally protects it against external influences. At the same time, the highly automated production line minimises manual handling, which further reduces the risk of breakage.

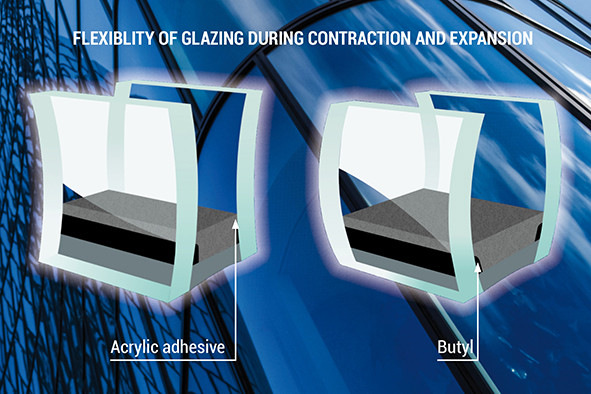

Why TPS is indispensable for thin glass

Glaston's proven TPS technology is essential for the production of this new thin glass insulating glass. It not only ensures high gas tightness and improved insulation values, but also flexible production. The system enables mixed production in which conventional and thin glass units can be manufactured in parallel - without changeover times or loss of quality.

Another technical highlight: The production line is equipped with two independent automatic assembly machines than can produce IG units in high-speed mode. The technology also allows a wide variety of shapes, giving architects and facade planners more creative freedom.

Glaston

Thin-glass insulating glass: Less weight, better insulation

The new triple TPS IG units offer up to 20 % better thermal insulation than conventional double Triple insulating glass - with reduced weight at the same time. This offers major advantages for renovations in particular: The reduced packet thickness allows them to be used in existing window frames, enabling quick and uncomplicated replacement.

The low weight also leads to easier handling during transport and installation, which makes construction projects more efficient. Functional problems such as the difficulty of closing heavy sliding windows can also be solved with thin glass insulating glass.

Also interesting: AGP takes advantage of the Glaston Autopilot on its tempering lines

‘The combination of higher light transmission, reduced use of materials and improved U-values makes this technology a real game changer in the glass industry,’ emphasises Uwe Risle, Head of Product Management Insulating Glass at Glaston.

Conclusion: Future technology for energy-efficient buildings

With the new TPS production line for thin glass IG units, Glaston has created a technical solution that offers decisive advantages for both new buildings and renovations. The innovative process sets new standards in insulating glass production and helps to meet the increasing requirements for energy-efficient construction methods.

Glaston