The demand for technology products has gone up particularly during the Covid pandemic, which has also led to an increased demand for silicon. In addition, the production of the crystalline semimetal in China, the world's largest producer, is currently being curtailed. The Chinese government has reduced the energy supply in many places in order to achieve its energy targets. This has also curbed the energy-intensive production of silicon. As if that were not enough, restricted sea and land freight routes are also complicating the supply chains.

Availability of silicones no longer certain

The result of all this is that prices for the industrial metal rose by about 300 % at the end of last year. An evaluation by the China Nanferraus Metals Industry Association showed that. "This development is not only putting the technology and automotive industries in a bind, but also window manufacturers," says Michael Merkle, Key Account Manager Direct Glazing at H.B. Fuller | Kömmerling. This is because silicon is used, among other things, to produce silicone for direct glazing - i.e. the bonding of the insulating glass pane in the window sash. "The availability of silicone is no longer certain for many window manufacturers," Michael Merkle continues. "But we have an alternative product in our portfolio that has been used for years, for which the raw materials are sufficiently available and can be procured without delivery problems. Production and construction sites can therefore continue." We are talking about the window adhesive Ködiglaze P, which is made using the raw material polyurethane.

H.B. Fuller | Kömmerling

Material-compatible, certified alternative

A key factor for the lasting durability of the bond, even with polyurethane, is the compatibility with all contact materials in and around the window. "Ködiglaze P has been successfully used for years for window bonding with all frame materials from wood to plastic to aluminium," explains Merkle. "Years of cooperation with all leading profile system providers have shown us that the polyurethane adhesive is very compatible with standard insulating glass sealants and PVB films on the market."

The product has been tested and approved according to RAL-GZ 716, Part 2 and the ift guideline VE-08/4. In addition, the adhesive has passed the glass bonding test according to DIN EN 1627 up to resistance class RC4. Therefore, direct glazing using Ködiglaze P provides end users with increased intrusion protection even with a standard window.

H.B. Fuller | Kömmerling

Uncomplicated re-tooling for polyurethane adhesive

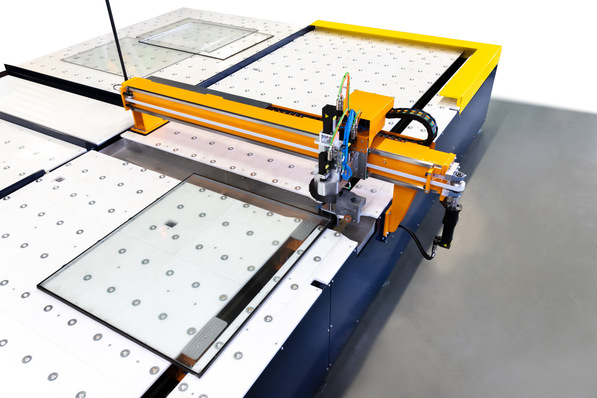

The silicone alternative can be processed as a one-component or two-component system and can be used in both manual and fully automated bonding systems. Thus, Ködiglaze P is suitable both as an alternative for small window manufacturing companies and for large-scale industrial production. "For smaller companies, the 600 ml film bag can be used with commercially available applicators, which are commonly available - and this for construction site applications as well as for small-series production." Industrial production can also be easily converted to Ködiglaze P. "The machine manufacturers who work with us have extensive experience with our adhesives and can adapt the machines to this one with minor adjustments".